reinforcing for cementitious composites

Reinforcement only comprises 1-5% of reinforced concrete by volume but it is extremely vulnerable to corrosion when made from carbon steel. All carbon steel is protected from the development of corrosion by a thin layer of protective oxide film on the surface of the material. This “passive layer” is a limited amount of corrosion propagated by the high alkalinity of concrete, and if left intact, protects the underlying steel from further degradation. However, de-icing salts or salt-water spray in some environments and even CO2 are slowly absorbed by the concrete, which causes the passive layer to fail and corrosion to develop, resulting in the concrete structure’s inevitable failure. Corrosion resistant rebar, such as epoxy-coated and galvanized rebar, attempt to mitigate this process though the use of an applied barrier that resists chloride and CO2 ingress, while non-corroding rebar, such as stainless steel and FRP rebar, are made from materials that prevent corrosion initiation entirely.

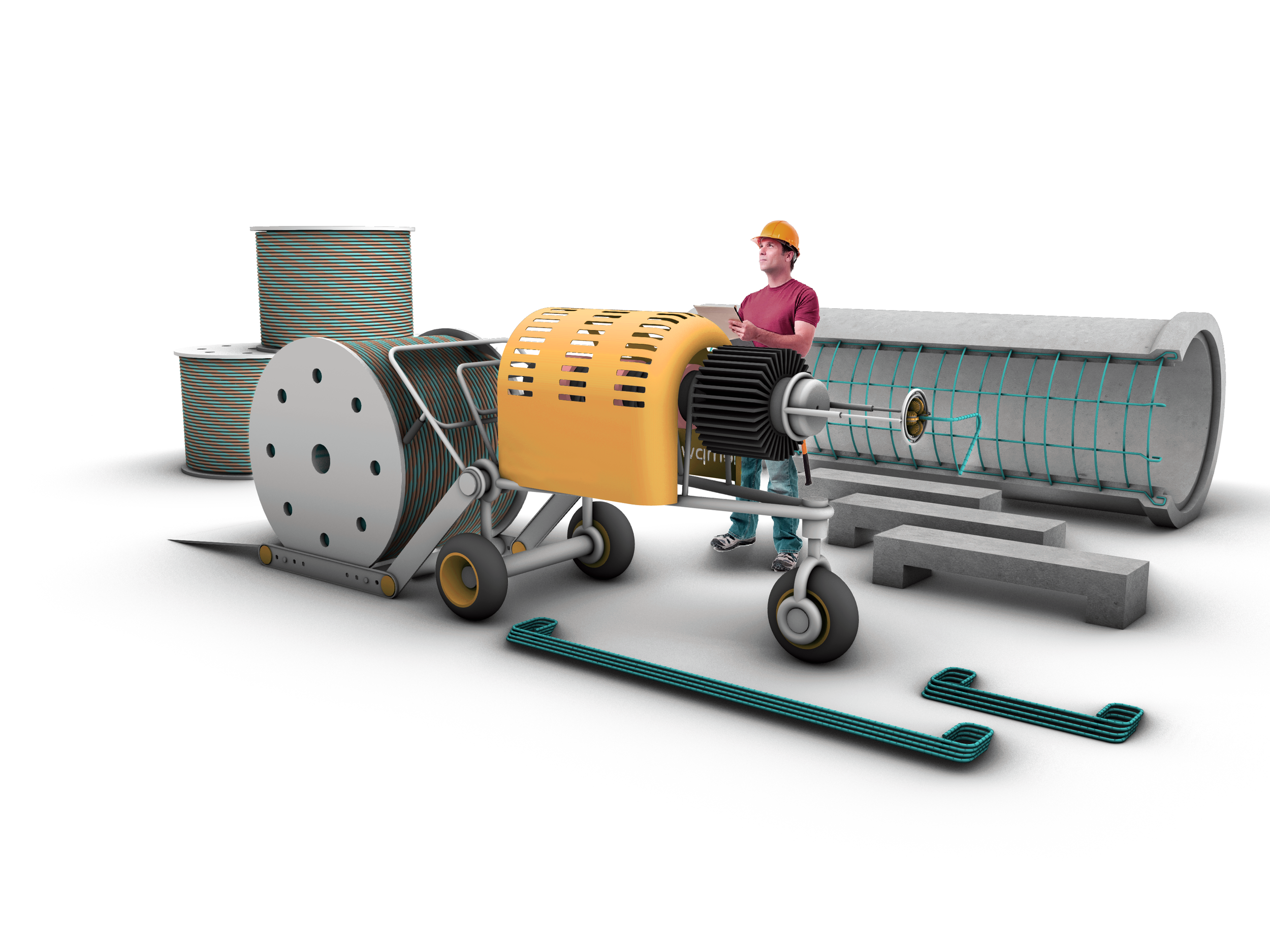

FibreWerks is developing reinforcing from a composite material consisting of natural fiber and bio-based or recycled thermoplastic matrix, called natural fiber-reinforced thermoplastic (NFRT), using a unique rapid pultrusion process. The feedstock for NFRT is a rope preform consisting of unidirectional natural fiber yarns (e.g., hemp, flax) as reinforcement commingled with thermoplastic filaments as the matrix that are all bound tightly together within a braided thermoplastic sleeve. Instead of a rack of reinforcement and polymer filament reels on a creel feeding a traditional pultruder, the unconsolidated rope wound on a large reel feeds into our compact pultrusion machine to simplify production of composite rebar either in a microfactory or at a construction job site.